|

||

|

||

|

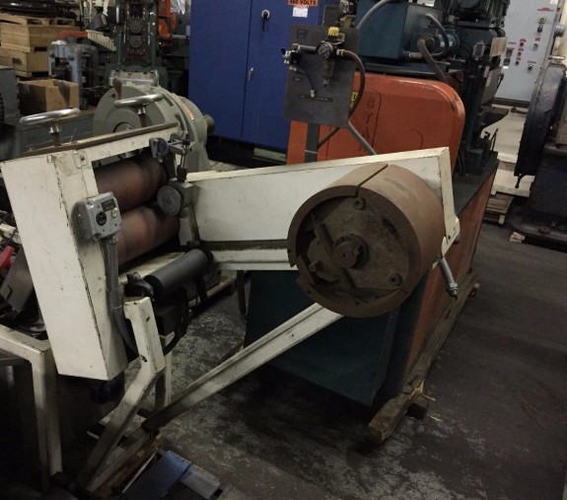

SPECIFICATIONS:

Electrically Heated, Continuous Strip-Annealing Unit with

an Angular Hearth and Water Quench Tank, Includes a

Recoiler and a Built-In Dissociator

Heat Zone: 8" Wide x 3" High x 108" Long

Coolant Quench Tank: 22" Wide x 20" High, 48" Long

Combination Unit Width: 36"

Length of Unit, Including Quench Tank, Approx.: 22'

Height of Unit: 48"

Single Muffle Design:

1/4" Thick Diamond Shape Muffle

9" Wide x 3" High Work Space at the Muffle Center

Muffle is of all TIG Welded Deisgn and Extends

Through the Furnace Entrance

Sealed Atmosphere Box

Extends Through the Furnace Exit and Enters the

Water Quench Tank

Kilowatt Rating of Furnace: 220/60/3,

80 Line Amps +/- 20%

Furance Direction: Left to Right

EQUIPPED WITH:

Temeperature Control:

There are two Watlow microprocessor-based

auto-tuning controls for heating up to approximately

1500 degrees F. This divides the heat zone into two

zones. Each zone is monitored for oven temperature

by two Watlow over-temperature limit controls. All

controls are calibrated for type (K) thermocouples.

Cooling Quench Tank:

Stainless steel material. There is a 4" diameter

polymer drum for guiding the strip stock through

the water tank.

Panel Board

Drive System:

The drive system consists of a pair of rubber pinch

rolls with soft rubber, geared for speeds up to

144 inches per minute. There is a "V" groove bearing

assembly adjustable to 8" wide to guide strip into

the pinch rolls

Recoiler:

14" diamter x 9" wide collapsible drum

RETURN

to complete inventory display

RETURN

to our home page